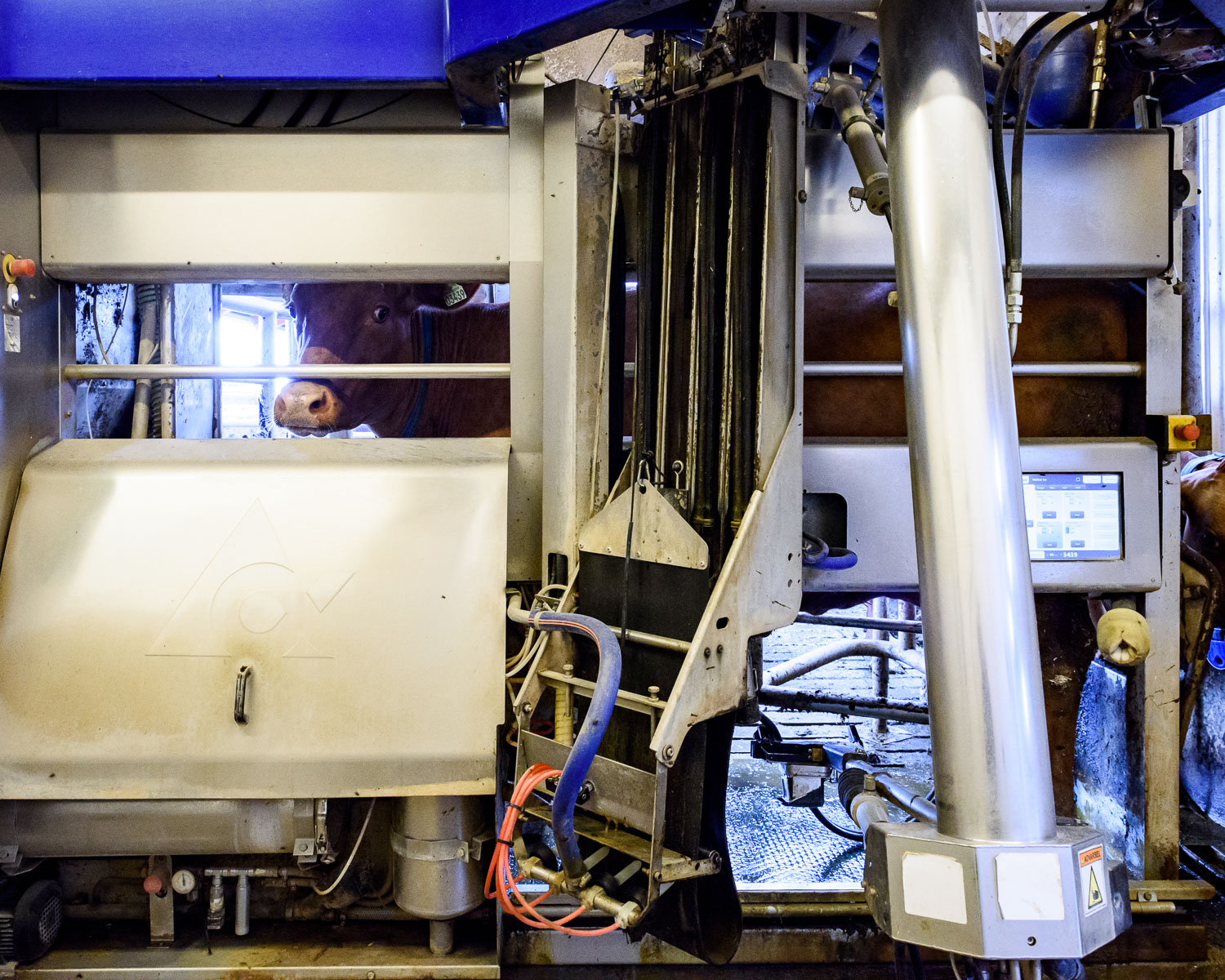

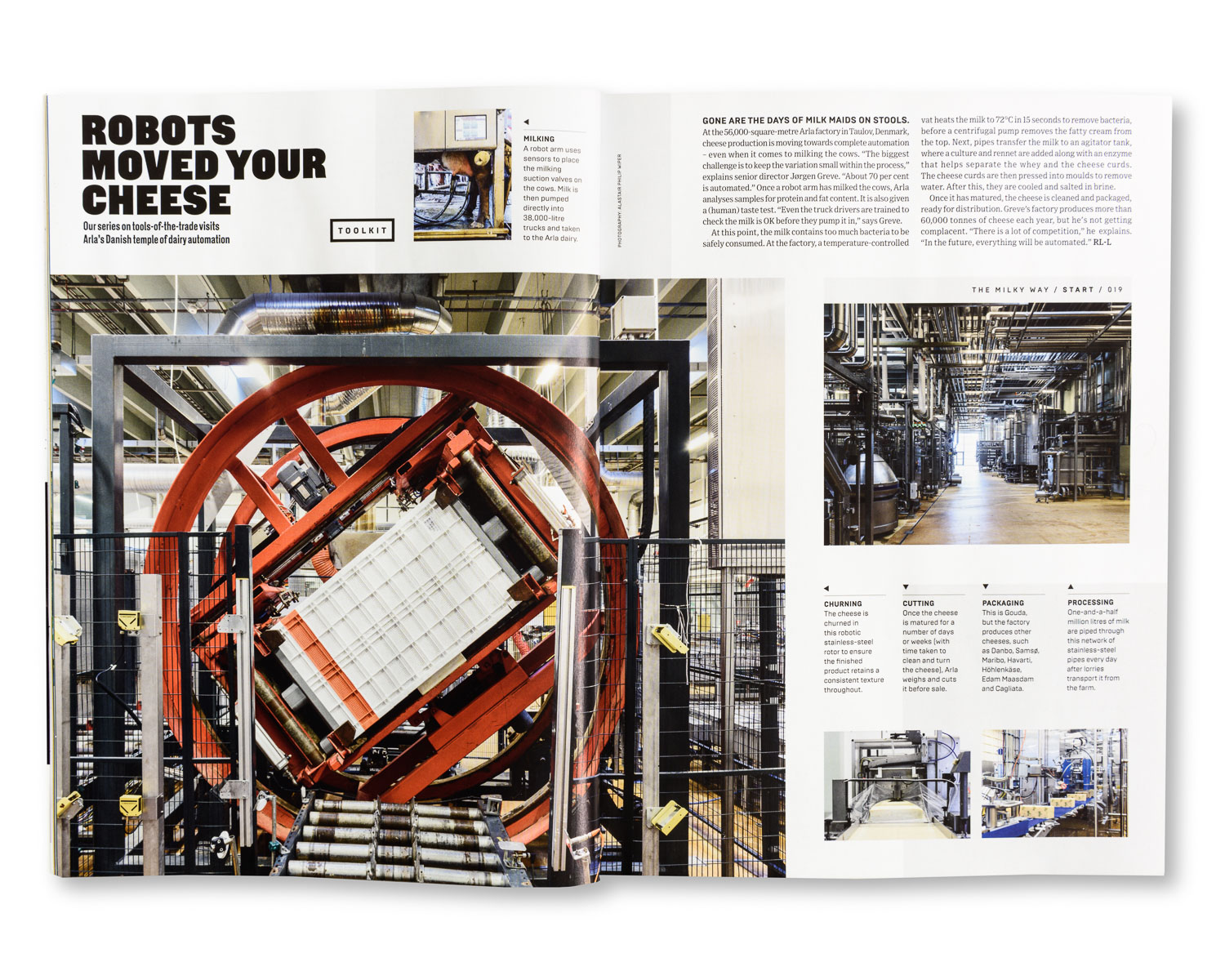

Cheese being turned during the maturation period at Taulov Dairy, Denmark

Arla Foods is the biggest producer of dairy products in Scandinavia. It is a cooperative owned by over 7,000 Danish and Swedish farmers, and it is the seventh largest dairy company in the world measure by turnover. I followed the process of some of their cheese being made, from the milking of the cows to the cheese production at one of their huge dairies in Taulov, Denmark.

The journey started at the organic dairy farm of Peter Sivertsen, just outside Roskilde in Eastern Denmark. Peter's farm produces organic fresh milk, and while he does not supply the dairy at Taulov, he says "The milking process for cheese production is exactly the same as we do it here. As part of Arla, every farm has to adhere to the same standards as every other in Arla - the same safety, bacteria levels, cell counts and so on. The type of cow used is also the same for fresh milk and cheese production."

"I am the 4th generation of my family on this farm, my great grandfather bought the farm in 1904. We turned organic in 1998 and put up this barn here, where we have 155 dairy cows producing 4,200 litres of milk every day. We also have 10 chickens and 20 cats."

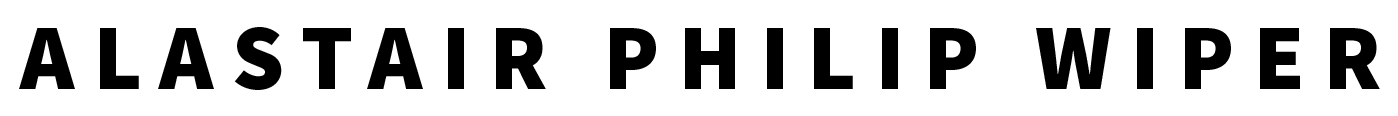

Peter's farm uses automatic robot milkers, which they installed eight years ago. "Before that we were milking in a milking parlour, and it was quite efficient but my arms couldn’t handle it, so we switched to the robot system. The cows get a treat when they come to the milker, so they come voluntarily to be milked." Upon entering the milker, each cow is electronically tagged and weighed, and the amount of milk that it has produced in the last 24 hours is noted - if it is too recent since the last milking, the cow is let out of the robot milker without being milked and will return later. On average they are milked 2.5 times per day, and the milker runs 24 hours a day. While I was visiting, there was about 20 cows lined up and awaiting their turn in the milker.

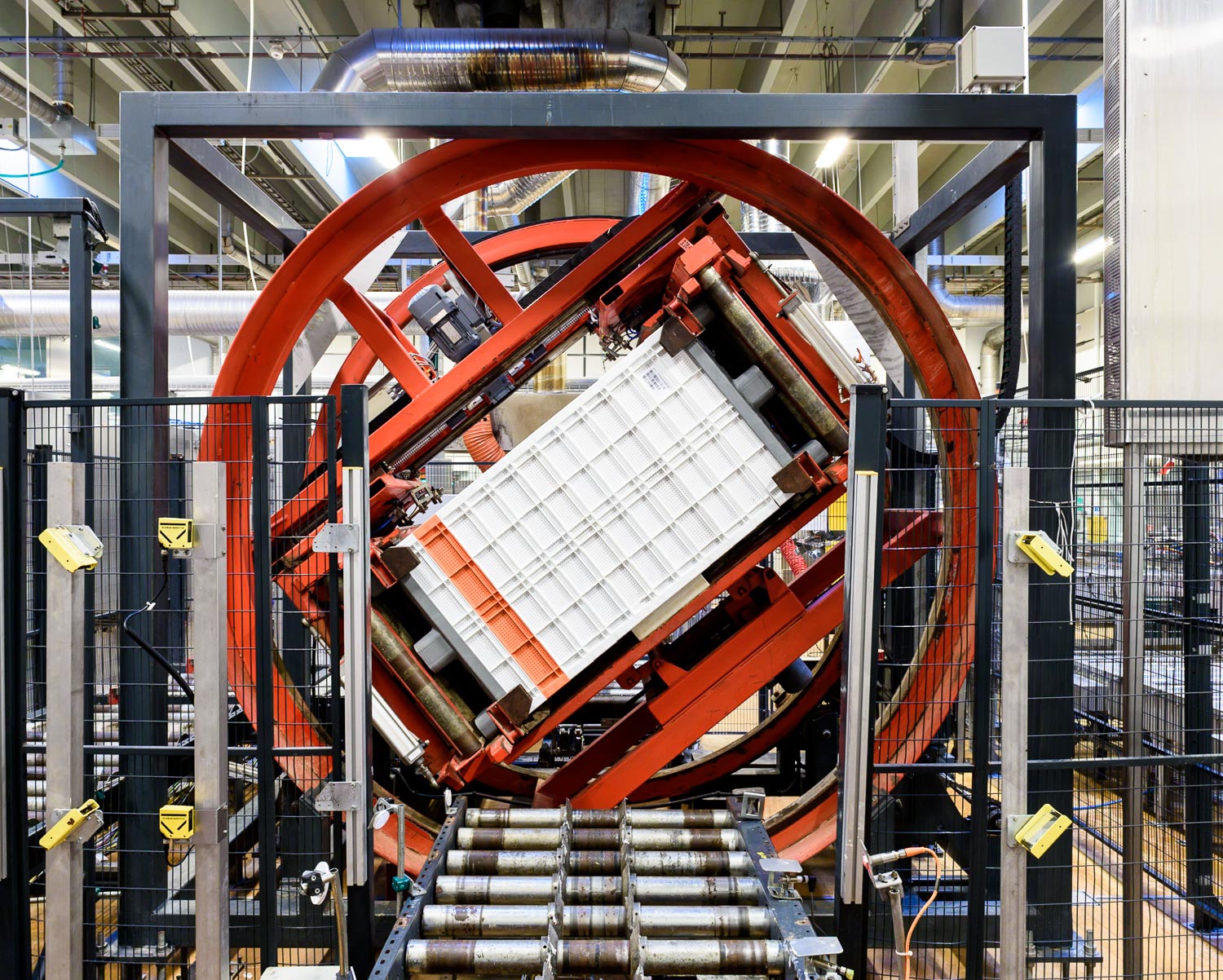

Milk is collected from the farms and sent for processing. In Jutland, some of that milk arrives at Taulov Dairy - between 1.5 and 2 million litres per day. The dairy opened in 2000, and uses 620,000 tonnes of milk to produce 60,000 tonnes of cheese per year. It produces Danish cheeses such as Danbo, Samsø and Haverti, as well as generic semi-hard cheeses for industrial use such as Gouda and Edam. 70 different recipes are used at the dairy, and 60% of the production is for the export market.

Jørgen Greve has worked for Arla for more than 35 years, and has been director of Taulov dairy since it opened. He told me about the way the dairy works.

"The process of turning the milk into cheese before it goes into storage takes between 36-48 hours. We mostly produce medium aged cheese, and it takes 2-3 months for the cheese to age. We need to adjust the composition of every cheese depending on how old we want it to be, so every cheese has it’s own recipe, it is not simply left longer if we want a mature cheese. The quickest cheese we produce here takes about one week, a Cagliata cheese which is produced for the Italian market. It is a very fresh cheese that is turned into mozzarella in the food service industry.

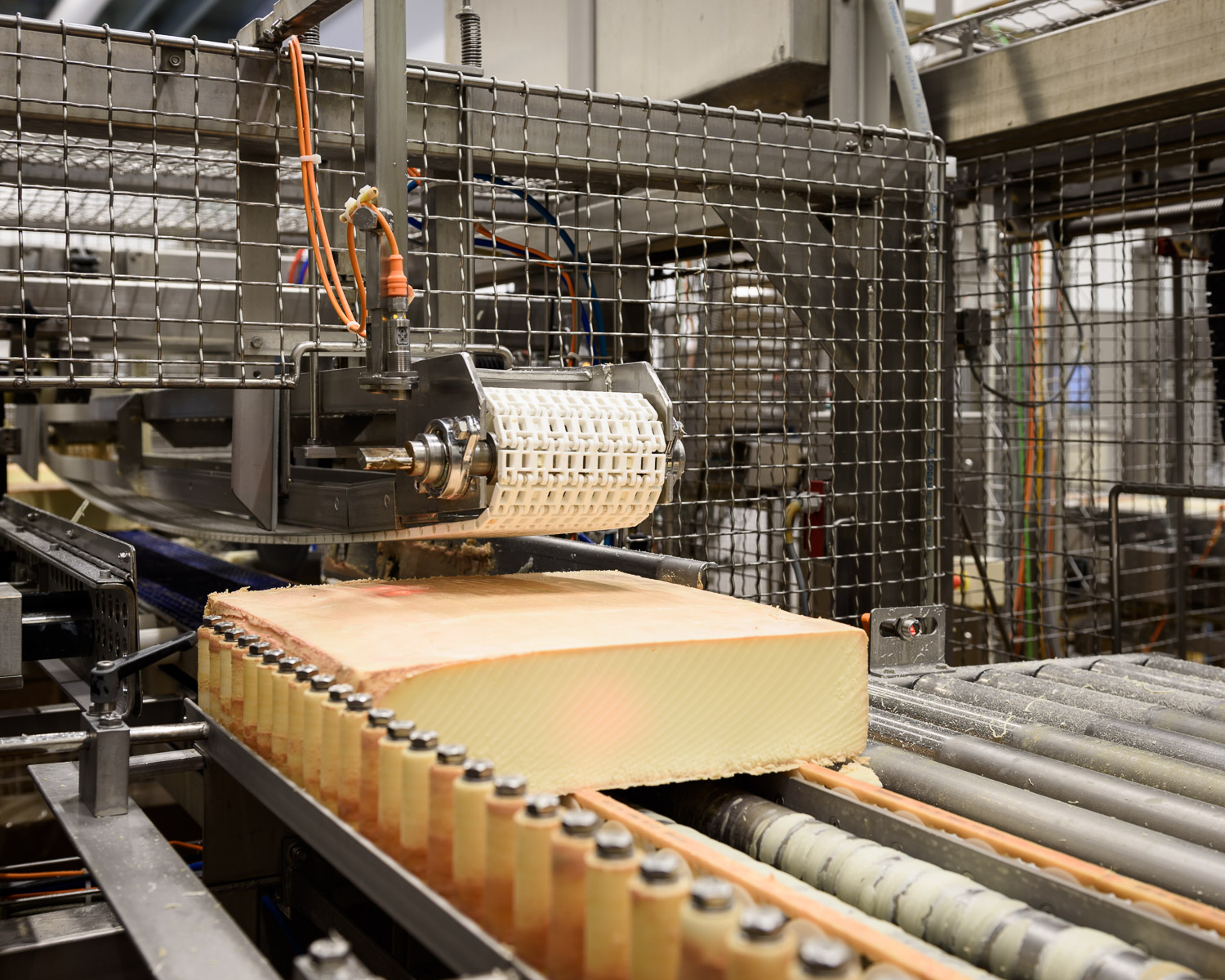

We make cheese in exactly the same way we did 100 years ago. We pasteurise the milk, we adjust the milk to the type of cheese we want to make - more precisely today than we did before because we know more about the protein in the milk and the way the milk changes with the seasons. These days we also use a closed cheese vat, but it used to be an open vat. We also produce our own bacterial culture for the cheese, in the same way it has always been done, and it is a living thing that we are very careful to protect - in the old days the cultures were not looked after as well so different types of bacteria could enter them, but we take a lot of care to make sure ours here stays exactly as we want it. Most of the cheeses we produce here have been around since before WW2, but these days we are much more careful with the cheese, it is not touched by hand, and everything is very carefully monitored.

The by-products we produce have also grown in value recently - things which were simply by-products in the 90s are now high value products. The whey concentrate and lactose that we take out are now high value products, used in things like baby milk, and the left over cream we have is used in Lurpack butter. We also have a lot of left-over water from the cow that we are constantly working to re-use.”

Featured in Wired UK, March 2017.